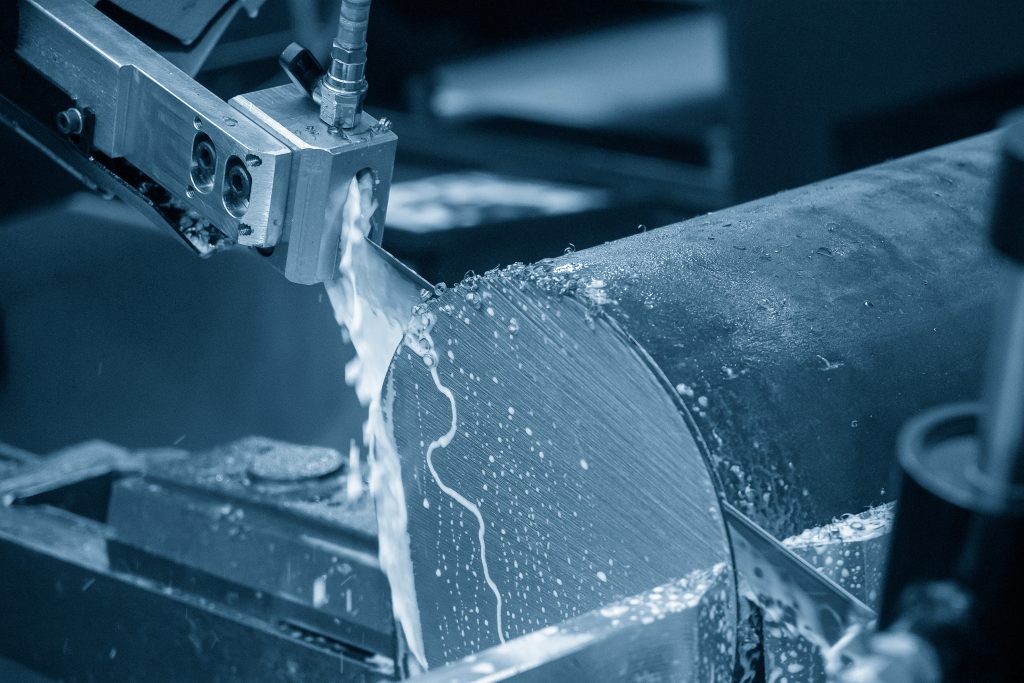

Machining

Precision mechanical parts for aerospace and defense industry and tooling manufacturing.

What can we do for you?

Turning

Milling

WEDM Electrical Discharge Cutting

Grinding

Slotting

Cut

Do you have any questions?

Machining in our offer

Thanks to its extensive machine park, Fin Sp. z o. o. can provide a wide range of services related to metalworking, both prototype and high-series. It has an advanced quality control system, which affects the great possibilities related to measurement technology. Thanks to fully automated CNC machining, up to 9 is able to carry out even the most complex orders, both design and production for mechanical and electronic teams.

Due to its wide possibilities related to metalworking, FIN Sp. z o.o. It is developing as a manufacturer of parts for the aerospace and defense industries. It is also a cooperator for the automotive industry.

Continuous optimization of production processes, personnel involved in the development policy and investments in modern machinery make the company strengthen its position on the market.

Processing of metals and engineering plastics:

- Inconel,

- Alloy steel

- Aluminium,

- Titanium,

- PE, POM C/H.

Production according to the highest standards:

The production is based on the highest industry standards, as evidenced by prestigious certificates and approvals. AS9100 certification demonstrates that our processes meet the stringent requirements of the aerospace and defense industry. We also have Part 21G approval, which means that we operate in accordance with the guidelines of the European Aviation Safety Agency (EASA). The concession of the Ministry of Interior and Administration emphasizes the ability to meet strict safety standards and regulations, ensuring a high level of quality and advanced control over production operations. With these certifications and approvals, we can guarantee our customers products of the highest quality, in accordance with the latest technical standards.